Manage the assembly process and coordinate the logistics of shipping equipment, ensuring that all components are delivered on time and in the correct order.

Solving Industry Challenges

Coordinating the assembly and shipping of wind farm components can be logistically complex. Delays in shipment or issues with assembly can cause significant project setbacks, particularly with large, heavy equipment and materials.

Shoreline’s Assembly and Shipping product optimizes logistics, providing real-time tracking and scheduling of shipments and assembly processes. This ensures timely delivery of components and smooth coordination between teams, reducing delays and improving project efficiency.

Ensure all components arrive on time and in the correct sequence for efficient assembly

Coordinate multimodal shipping and storage logistics to avoid delays and bottlenecks

Streamline the assembly process and optimize shipping workflows to reduce project risk

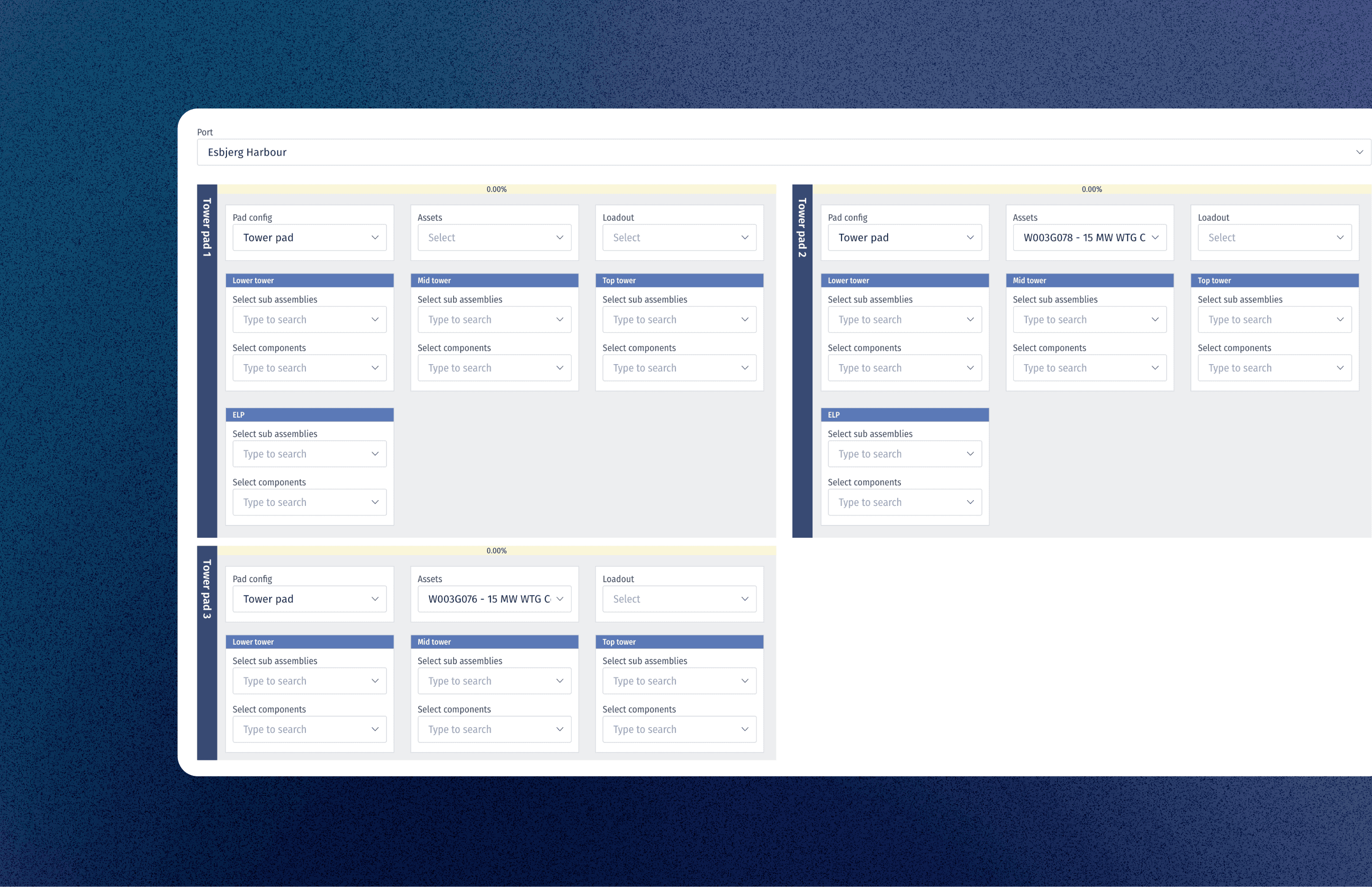

Optimised pre-assembly and load-out sequencing for shipping readiness

Plan and simulate the pre-assembly tasks (tower sections, nacelle integration) and coordinate load-out operations with vessel scheduling to ensure timely dispatch and arrival at site.

Strategic shipping logistics and route optimisation across transport modes

Select optimal shipping routes and transport methods, integrate weather and port constraints, and manage multimodal transfers (truck, barge, vessel) to minimise risk and transit time.

Seamless transition from shipment to on-site assembly and commissioning

Coordinate the hand-over from logistics to on-site assembly teams, ensure all materials and equipment arrive in scope and sequence, and support installation readiness to drive project momentum.

Check out our latest success stories

Ready to Build Smarter?

Request a custom quote and explore the Shoreline platform in action.

Discover the ROI of your next wind project

Estimate the financial impact of smarter planning and execution with Shoreline and see how much value your project can unlock.